Influencia de la escoria de cobre como material cementicio suplementario en morteros

Influence of copper slag as supplementary cementitious material in mortar

Barra lateral del artículo

Términos de la licencia (VER)

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

Declaración del copyright

Los autores ceden en exclusiva a la Universidad EIA, con facultad de cesión a terceros, todos los derechos de explotación que deriven de los trabajos que sean aceptados para su publicación en la Revista EIA, así como en cualquier producto derivados de la misma y, en particular, los de reproducción, distribución, comunicación pública (incluida la puesta a disposición interactiva) y transformación (incluidas la adaptación, la modificación y, en su caso, la traducción), para todas las modalidades de explotación (a título enunciativo y no limitativo: en formato papel, electrónico, on-line, soporte informático o audiovisual, así como en cualquier otro formato, incluso con finalidad promocional o publicitaria y/o para la realización de productos derivados), para un ámbito territorial mundial y para toda la duración legal de los derechos prevista en el vigente texto difundido de la Ley de Propiedad Intelectual. Esta cesión la realizarán los autores sin derecho a ningún tipo de remuneración o indemnización.

La autorización conferida a la Revista EIA estará vigente a partir de la fecha en que se incluye en el volumen y número respectivo en el Sistema Open Journal Systems de la Revista EIA, así como en las diferentes bases e índices de datos en que se encuentra indexada la publicación.

Todos los contenidos de la Revista EIA, están publicados bajo la Licencia Creative Commons Atribución-NoComercial-NoDerivativa 4.0 Internacional

Licencia

![]()

Esta obra está bajo una Licencia Creative Commons Atribución-NoComercial-NoDerivativa 4.0 Internacional

Contenido principal del artículo

Resumen

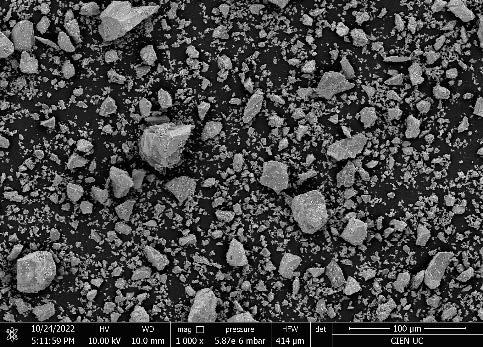

La demanda de cemento Portland (OPC) impacta de gran manera el medio ambiente, debido a la generación de gases de efecto invernadero y el consumo de materias primas no renovables durante su fabricación. Por tal razón, la búsqueda de materiales alternativos para disminuir el consumo de cemento es vital en la búsqueda de la sustentabilidad. Por esta razón, la escoria de cobre (EC) como materia cementicio suplementario (SCM) en la elaboración de morteros con menor contenido de OPC es una opción para generar un ambiente sostenible. Este estudio, investigo la influencia de la EC frente a la trabajabilidad, resistencia a la compresión y resistencia a la flexión a diferentes edades de curado. Morteros con 0%, 10%, 20%, 30%, 40% y 50% de EC como reemplazo parcial de OPC se elaboraron, donde se evidencio una mayor fluidez en los morteros con EC. Las propiedades mecánicas, se vieron afectas de manera monotónica en las primeras edades evaluadas (7, 28 y 90 días), donde los morteros con mayor contenido de EC presentaron la mayor perdida de resistencia. Sin embargo, a los 150 días de curado, la mezcla 10% EC presento una resistencia a la compresión de 43,6 MPa, 7,6% mayor que la mezcla de referencia.

Descargas

Detalles del artículo

Yimmy Fernando Silva Urrego, Pontificia Universidad Católica de Chile - Chile

Estudiante de doctorado en Ingeniería con énfasis en ingeniería de materiales, de la Universidad del Valle.

Referencias (VER)

Al Biajawi, M. I., Embong, R., Muthusamy, K., Ismail, N., & Obianyo, I. I. (2022). Recycled coal bottom ash as sustainable materials for cement replacement in cementitious Composites: A review. Construction and Building Materials, 338(May). https://doi.org/10.1016/j.conbuildmat.2022.127624

ASTM C150. (2022). Standard Specification for Portland Cement. ASTM International, West Conshohocken, PA. 1–9. https://doi.org/10.1520/C0150

ASTM C230. (2021). Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. 1–7. https://doi.org/10.1520/C0230

Ayati, B., Newport, D., Wong, H., & Cheeseman, C. (2022). Low-carbon cements: Potential for low-grade calcined clays to form supplementary cementitious materials. Cleaner Materials, 5, 100099. https://doi.org/10.1016/j.clema.2022.100099

Bahurudeen, A., Wani, K., Basit, M. A., & Santhanam, M. (2016). Assesment of Pozzolanic Performance of Sugarcane Bagasse Ash. Journal of Materials in Civil Engineering, 28(2), 1–11. https://doi.org/10.1061/(asce)mt.1943-5533.0001361

Bheel, N., Ali, M. O. A., Shafiq, N., Almujibah, H. R., Awoyera, P., Benjeddou, O., Shittu, A., & Olalusi, O. B. (2023). Utilization of millet husk ash as a supplementary cementitious material in eco-friendly concrete: RSM modelling and optimization. Structures, 49(February), 826–841. https://doi.org/10.1016/j.istruc.2023.02.015

Çelik, D. N., Demircan, R. K., Shi, J., Kaplan, G., & Durmuş, G. (2023). The engineering properties of high strength mortars incorporating juniper seed ash calcined at different temperatures: Comparison with other SCMs. Powder Technology, 422(March). https://doi.org/10.1016/j.powtec.2023.118474

Chang, Z., Long, G., Xie, Y., & Zhou, J. L. (2022). Chemical effect of sewage sludge ash on early-age hydration of cement used as supplementary cementitious material. Construction and Building Materials, 322(January). https://doi.org/10.1016/j.conbuildmat.2021.126116

Cruz Juarez, R. I., & Finnegan, S. (2021). The environmental impact of cement production in Europe: A holistic review of existing EPDs. Cleaner Environmental Systems, 3(August). https://doi.org/10.1016/j.cesys.2021.100053

Edwin, R. S., De Schepper, M., Gruyaert, E., & De Belie, N. (2016). Effect of secondary copper slag as cementitious material in ultra-high performance mortar. Construction and Building Materials, 119, 31–44. https://doi.org/10.1016/j.conbuildmat.2016.05.007

Fernando, Y., Urrego, S., Rojas, J. E., & Gamboa, J. A. (2019). diseño de mezcla de vértices extremos , en concretos y cal hidratada Artículo en prensa / Article in press Optimization of Compressive Strength Using Design of Extreme Vertices Mixing , in Ternary Concretes Based desenho de mescla de vértices estremos , e. Revista EIA, 57(2), 99–113.

Galusnyak, S. C., Petrescu, L., & Cormos, C. C. (2022). Environmental impact assessment of post-combustion CO2 capture technologies applied to cement production plants. Journal of Environmental Management, 320(July). https://doi.org/10.1016/j.jenvman.2022.115908

Gopalakrishnan, R., & Nithiyanantham, S. (2020). Microstructural, mechanical, and electrical properties of copper slag admixtured cement mortar. Journal of Building Engineering, 31(March). https://doi.org/10.1016/j.jobe.2020.101375

Hafez, H., Teirelbar, A., Tošić, N., Ikumi, T., & de la Fuente, A. (2023). Data-driven optimization tool for the functional, economic, and environmental properties of blended cement concrete using supplementary cementitious materials. Journal of Building Engineering, 67(January). https://doi.org/10.1016/j.jobe.2023.106022

Ige, O. E., Olanrewaju, O. A., Duffy, K. J., & Obiora, C. (2021). A review of the effectiveness of Life Cycle Assessment for gauging environmental impacts from cement production. Journal of Cleaner Production, 324(September). https://doi.org/10.1016/j.jclepro.2021.129213

Jin, L., Chen, M., Wang, Y., Peng, Y., Yao, Q., Ding, J., Ma, B., & Lu, S. (2023). Utilization of mechanochemically pretreated municipal solid waste incineration fly ash for supplementary cementitious material. Journal of Environmental Chemical Engineering, 11(1). https://doi.org/10.1016/j.jece.2022.109112

Jones, C., Ramanathan, S., Suraneni, P., & Hale, M. (2023). Mitigating calcium oxychloride formation in cementitious paste using alternative supplementary cementitious materials. Construction and Building Materials, 377(May 2022).

Kumar, A., & Tejaswini, M. L. (2022). Studies on hardened properties of concrete incorporated with copper slag. Materials Today: Proceedings, 60, 646–657. https://doi.org/10.1016/j.matpr.2022.02.264

Leong, G. W., Pahdili, E. H. H., Mo, K. H., & Ibrahim, Z. (2022). Impacts of polyvinyl alcohol and basalt fibres on green fly ash cenosphere lightweight cementitious composite. Materials Today: Proceedings, 61, 512–516. https://doi.org/10.1016/j.matpr.2021.12.519

Liang, X., Dang, W., Yang, G., & Zhang, Y. (2023). Environmental feasibility evaluation of cement co-production using classified domestic waste as alternative raw material and fuel: A life cycle perspective. Journal of Environmental Management, 326(November 2022). https://doi.org/10.1016/j.jenvman.2022.116726

Li, W., Hua, L., Shi, Y., Wang, P., Liu, Z., Cui, D., & Sun, X. (2022). Influence of metakaolin on the hydration and microstructure evolution of cement paste during the early stage. Applied Clay Science, 229(July). https://doi.org/10.1016/j.clay.2022.106674

Li, Z., Gao, X., Lu, D., & Dong, J. (2022). Early hydration properties and reaction kinetics of multi-composite cement pastes with supplementary cementitious materials (SCMs). Thermochimica Acta, 709(September 2021). https://doi.org/10.1016/j.tca.2022.179157

Mirnezami, S. M., Hassani, A., & Bayat, A. (2023). Evaluation of the effect of metallurgical aggregates (steel and copper slag) on the thermal conductivity and mechanical properties of concrete in jointed plain concrete pavements (JPCP). Construction and Building Materials, 367(January). https://doi.org/10.1016/j.conbuildmat.2022.129532

Navarrete, I., Kurama, Y., Escalona, N., Brevis, W., & Lopez, M. (2022). Effect of supplementary cementitious materials on viscosity of cement-based pastes. Cement and Concrete Research, 151(February 2021). https://doi.org/10.1016/j.cemconres.2021.106635

Ndahirwa, D., Zmamou, H., Lenormand, H., & Leblanc, N. (2022). The role of supplementary cementitious materials in hydration, durability and shrinkage of cement-based materials, their environmental and economic benefits: A review. Cleaner Materials, 5(July). https://doi.org/10.1016/j.clema.2022.100123

Panda, S., & Sarkar, P. (2022). Abrasion resistance of copper slag aggregate concrete designed by Taguchi method. Materials Today: Proceedings, 65, 434–441. https://doi.org/10.1016/j.matpr.2022.02.545

Pang, L., Liu, Z., Wang, D., & An, M. (2022). Review on the Application of Supplementary Cementitious Materials in Self-Compacting Concrete. Crystals, 12(2). https://doi.org/10.3390/cryst12020180

Rohith, N., & Ravikumar, M. S. (2022). Strength characteristics of concrete made with copper slag and fly-ash. Materials Today: Proceedings, 60, 738–745. https://doi.org/10.1016/j.matpr.2022.02.337

Santos, T. A., Cilla, M. S., & Ribeiro, e D. V. (2022). Use of asbestos cement tile waste (ACW) as mineralizer in the production of Portland cement with low CO2 emission and lower energy consumption. Journal of Cleaner Production, 335(May 2021), 130061. https://doi.org/10.1016/j.jclepro.2021.130061

Shahas, S., Girija, K., & Nazeer, M. (2022). Evaluation of pozzolanic activity of ternary blended supplementary cementitious material with rice husk ash and GGBS. Materials Today: Proceedings, xxxx, 2–7. https://doi.org/10.1016/j.matpr.2023.01.073

Sharma, P., Sharma, N., & Kumar Parashar, A. (2022). Scientific investigation of metakaolin-based cement concrete with rock sand infill. Materials Today: Proceedings, 62, 4147–4150. https://doi.org/10.1016/j.matpr.2022.04.674

Sharma, R., & Khan, R. A. (2017). Sustainable use of copper slag in self compacting concrete containing supplementary cementitious materials. Journal of Cleaner Production, 151, 179–192. https://doi.org/10.1016/j.jclepro.2017.03.031

Sheikh, E., Mousavi, S. R., & Afshoon, I. (2022). Producing green Roller Compacted Concrete (RCC) using fine copper slag aggregates. Journal of Cleaner Production, 368(December 2021). https://doi.org/10.1016/j.jclepro.2022.133005

Silva, Y. F., Izquierdo, S. R., & Delvasto, S. (2019). Effect of masonry residue on the hydration of portland cement paste. DYNA (Colombia), 86(209), 367–377. https://doi.org/10.15446/dyna.v86n209.77286

Silva, Y. F., Lange, D. A., & Delvasto, S. (2019). Effect of incorporation of masonry residue on the properties of self-compacting concretes. Construction and Building Materials, 196. https://doi.org/10.1016/j.conbuildmat.2018.11.132

Sousa, V., & Bogas, J. A. (2021). Comparison of energy consumption and carbon emissions from clinker and recycled cement production. Journal of Cleaner Production, 306. https://doi.org/10.1016/j.jclepro.2021.127277

Sridharan, M., & Madhavi, T. C. (2020). Investigating the influence of copper slag on the mechanical behaviour of concrete. Materials Today: Proceedings, 46, 3225–3232. https://doi.org/10.1016/j.matpr.2020.11.195

Teymouri, M., & Shakouri, M. (2023). Optimum pretreatment of corn stover ash as an alternative supplementary cementitious material. 12(March).

Wang, D., Wang, Q., & Huang, Z. (2020). Reuse of copper slag as a supplementary cementitious material: Reactivity and safety. Resources, Conservation and Recycling, 162(April). https://doi.org/10.1016/j.resconrec.2020.105037

WBCSD. (2018). Cement technology roadmap shows how the path to achieve CO2 reductions up to 24% by 2050. https://www.wbcsd.org/Sector-Projects/Cement-Sustainability-Initiative/News/Cement-technology-roadmap-shows-how-the-path-to-achieve-CO2-reductions-up-to-24-by-2050

Zajac, M., Bolte, G., Skocek, J., & Ben Haha, M. (2021). Modelling the effect of the cement components fineness on performance and environmental impact of composite cements. Construction and Building Materials, 276. https://doi.org/10.1016/j.conbuildmat.2020.122108

Artículos similares

- Diógenes de Jesús Ramírez Ramírez , Cristian David Correa Álvarez, Laura Andrea Marín Ríos, Fortalecimiento del Pensamiento Computacional en Estudiantes de Secundaria Mediante la Programación con Arduino UNO , Revista EIA: Vol. 22 Núm. 44 (2025): Tabla de contenido Revista EIA No. 44

También puede {advancedSearchLink} para este artículo.

PDF

PDF

FLIP

FLIP