Alternativas de reutilización y valorización de residuos cerámicos: una revisión

Ceramic waste reuse and valorization alternatives: A review

Barra lateral del artículo

Términos de la licencia (VER)

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

Declaración del copyright

Los autores ceden en exclusiva a la Universidad EIA, con facultad de cesión a terceros, todos los derechos de explotación que deriven de los trabajos que sean aceptados para su publicación en la Revista EIA, así como en cualquier producto derivados de la misma y, en particular, los de reproducción, distribución, comunicación pública (incluida la puesta a disposición interactiva) y transformación (incluidas la adaptación, la modificación y, en su caso, la traducción), para todas las modalidades de explotación (a título enunciativo y no limitativo: en formato papel, electrónico, on-line, soporte informático o audiovisual, así como en cualquier otro formato, incluso con finalidad promocional o publicitaria y/o para la realización de productos derivados), para un ámbito territorial mundial y para toda la duración legal de los derechos prevista en el vigente texto difundido de la Ley de Propiedad Intelectual. Esta cesión la realizarán los autores sin derecho a ningún tipo de remuneración o indemnización.

La autorización conferida a la Revista EIA estará vigente a partir de la fecha en que se incluye en el volumen y número respectivo en el Sistema Open Journal Systems de la Revista EIA, así como en las diferentes bases e índices de datos en que se encuentra indexada la publicación.

Todos los contenidos de la Revista EIA, están publicados bajo la Licencia Creative Commons Atribución-NoComercial-NoDerivativa 4.0 Internacional

Licencia

![]()

Esta obra está bajo una Licencia Creative Commons Atribución-NoComercial-NoDerivativa 4.0 Internacional

Contenido principal del artículo

Resumen

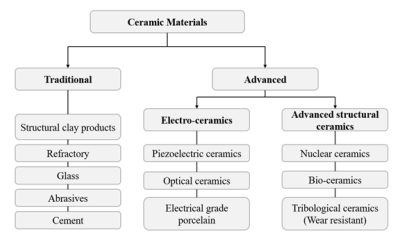

Los materiales cerámicos contribuyen con el mayor porcentaje de desechos dentro de los residuos generados en la construcción y demolición de estructuras de concreto. Actualmente estos desechos cerámicos se eliminan directamente en vertederos, debido a la falta de alternativas de disposición y al desconocimiento de opciones de aprovechamiento de estos materiales. El objetivo de este estudio es identificar las alternativas actuales y establecer las perspectivas de aprovechamiento y valorización de los residuos cerámicos. Este análisis de alternativas de aprovechamiento y valorización de los residuos cerámicos se lleva a cabo mediante una revisión bibliográfica, la cual está enfocada a identificar las opciones existentes en el aprovechamiento y valorización de los residuos de cerámico. Para cada alternativa existente se realiza una breve descripción de la metodología empleada y se destacan los principales resultados obtenidos en cada estudio. A partir de la revisión bibliográfica se plantean algunas perspectivas de aprovechamiento de materiales cerámicos. Se encontró que actualmente los residuos cerámicos se aprovechan principalmente en la formulación de concretos, fabricación de aislantes eléctricos, extracción de alúmina y como barrera geológica para contener residuos nucleares. Además, a partir de las propiedades de los materiales cerámicos, se establecieron como perspectivas de aprovechamiento la obtención de aislantes térmicos, materiales abrasivos, recuperación de arrecifes de coral y elaboración de estructuras a partir de técnicas de fabricación aditiva. Se concluye que la opción económicamente más rentable para el aprovechamiento y valorización de los residuos cerámicos es la formulación de concretos, mientras que la perspectiva más viable es la fabricación de materiales abrasivos.

Descargas

Detalles del artículo

Referencias (VER)

Alhabeeb, B. A., Mohammed, H. N., & Alhabeeb, S. A. (2021). Thermal insulators based on abundant waste materials. IOP Conference Series: Materials Science and Engineering, 1067(1), 012097. https://doi.org/10.1088/1757-899x/1067/1/012097

Awoyera, P. O., Ndambuki, J. M., Akinmusuru, J. O., & Omole, D. O. (2018). Characterization of ceramic waste aggregate concrete. HBRC Journal, 14(3), 282–287. https://doi.org/10.1016/j.hbrcj.2016.11.003

Blackett, G., Savory, E., Toy, N., Parke, G. A. R., Clark, M., & Rabjohns, B. (2008). An evaluation of the environmental burdens of present and alternative materials used for electricity transmission. Building and Environment, 43(7), 1326–1338. https://doi.org/10.1016/j.buildenv.2006.08.032

Belhouchet, K., Bayadi, A., Belhouchet, H., & Romero, M. (2019). Improvement of mechanical and dielectric properties of porcelain insulators using economic raw materials. Boletín De La Sociedad Española De Cerámica y Vidrio, 58(1), 28–37. https://doi.org/10.1016/j.bsecv.2018.05.004

Bhattacharyya, S., Das, S. K., & Mitra, N. K. (2005). Effect of titania on fired characteristics of triaxial porcelain. Bulletin of Materials Science, 28(5), 445–452. https://doi.org/10.1007/bf02711234

Bhogilal, V. R., & Tejas, M. (2018). Pertinence of Ceramic Waste in Self Compacted Concrete as Partial Equivalent of Cement. International Research Journal of Engineering and Technology, 5(11), 344–349. ISSN: 2395-0056

Bommisetty, J., Keertan, T. S., Ravitheja, A., & Mahendra, K. (2019). Effect of waste ceramic tiles as a partial replacement of aggregates in concrete. Materials Today: Proceedings, 19, 875–877. https://doi.org/10.1016/j.matpr.2019.08.230

Burger, W., & Kiefer, G. (2021). Alumina, zirconia, and their composite ceramics with properties tailored for medical applications. Journal of Composites Science, 5(11), 306. https://doi.org/10.3390/jcs5110306

Caligaris, R., Quaranta, N., Caligaris, M., & Benavidez, E. (2000). Materias Primas no tradicionales en la Industria Cerámica. Boletín De La Sociedad Española De Cerámica y Vidrio, 39(5), 623–626. https://doi.org/10.3989/cyv.2000.v39.i5.779

Cicek, B., Karadagli, E., & Duman, F. (2018). Valorisation of boron mining wastes in the production of wall and floor tiles. Construction and Building Materials, 179, 232–244. https://doi.org/10.1016/j.conbuildmat.2018.05.182

Contreras, J. (2014). Influencia de la inserción de nano-óxidos cerámicos sobre la microestructura y propiedades de una porcelana triaxial [Tesis de Doctorado, Universidad Autónoma de Nuevo León]. Repositorio institucional http://eprints.uanl.mx/11384/1/1080215587.pdf

Cozzarini, L., Marsich, L., Ferluga, A., & Schmid, C. (2020). Life Cycle Analysis of a novel thermal insulator obtained from recycled glass waste. Developments in the Built Environment, 3, 100014. https://doi.org/10.1016/j.dibe.2020.100014

Devanathan, R., Gao, F., & Sun, X. (2011). Challenges in modeling the degradation of ceramic waste forms, 1, 2–28. https://doi.org/10.2172/1043140

El-Dieb, A. S., & Kanaan, D. M. (2018). Ceramic waste powder an alternative cement replacement – characterization and evaluation. Sustainable Materials and Technologies, 17, 1–11. https://doi.org/10.1016/j.susmat.2018.e00063

El País. (2019, April 24). Ice proyecta instalación de megaestructura de arrecife artificial en Costa del Pacífico. Diario Digital Nuestro País. Retrieved December 1, 2022, from https://www.elpais.cr/2019/04/23/ice-proyecta-instalacion-de-megaestructura-de-arrecife-artificial-en-costa-del-pacifico/

European Commission. (2018). Energy Performance of Buildings directive. Energy performance of buildings directive. Retrieved December 1, 2022, from https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en

Fassbinder, G. (2002). A New Ceramic Body Concept for High Strength High Voltage Insulators. CFI Ceramic Forum International, 79, E17-E19. Disponible en: https://www.researchgate.net/publication/287903598_A_new_ceramic_body_concept_for_high_strength_high_voltage_insulators

Garza, J. (2019, April 25). Gobierno propone Construcción de Mega Arrecife artificial en el Pacífico. Periódico La República. Retrieved December 1, 2022, from https://www.larepublica.net/noticia/gobierno-propone-construccion-de-mega-arrecife-artificial-en-el-pacifico

Gress, R. I., & Leshchenko, N. P. (1969). Increasing the porcelain pitchers content in high-voltage porcelain bodies. Glass and Ceramics, 26(4), 249–252. https://doi.org/10.1007/bf00676453

Henao, L. F., & López, M. E. (2017). Caracterización y aprovechamiento de residuos sólidos de la industria electrocerámica, como fuente de extracción de alúmina. Revista Colombiana De Materiales, (10), 43–55. Recuperado de: https://revistas.udea.edu.co/index.php/materiales/article/view/328003

Hind, A. R., Bhargava, S. K., & Grocott, S. C. (1999). The surface chemistry of Bayer Process Solids: A review. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 146(1-3), 359–374. https://doi.org/10.1016/s0927-7757(98)00798-5

Huang, B., Li, C., Zhang, Y., Ding, W., Yang, M., Yang, Y., Zhai, H., Xu, X., Wang, D., Debnath, S., Jamil, M., Li, H. N., Ali, H. M., Gupta, M. K., & Said, Z. (2021). Advances in fabrication of ceramic corundum abrasives based on sol–gel process. Chinese Journal of Aeronautics, 34(6), 1–17. https://doi.org/10.1016/j.cja.2020.07.004

Hur, H., Jin Park, Y., Kim, D.-H., & Wan Ko, J. (2022). Material extrusion for ceramic additive manufacturing with polymer-free ceramic precursor binder. Materials & Design, 221, 110930. https://doi.org/10.1016/j.matdes.2022.110930

Huseien, G. F., Sam, A. R., Shah, K. W., & Mirza, J. (2020). Effects of ceramic tile powder waste on properties of self-compacted alkali-activated concrete. Construction and Building Materials, 236, 117-574. https://doi.org/10.1016/j.conbuildmat.2019.117574

INMR. (2021). Testing ageing of porcelain insulators. Retrieved November 16, 2022, from https://www.inmr.com/testing-ageing-of-porcelain-insulators/

Jain, P., Gupta, R., & Chaudhary, S. (2022). A literature review on the effect of using ceramic waste as supplementary cementitious material in cement composites on workability and compressive strength. Materials Today: Proceedings, 65, 871–876. https://doi.org/10.1016/j.matpr.2022.03.453

Jerônimo, V. L., Meira, G. R., & da Silva, L. C. (2018). Performance of self-compacting concretes with wastes from heavy ceramic industry against corrosion by chlorides. Construction and Building Materials, 169, 900–910. https://doi.org/10.1016/j.conbuildmat.2018.03.034

Juan, A., Medina, C., Guerra, I., Morán, J., Aguado, P., Sánchez, M., Frias, M., & Rodríguez, O. (2010). Re-use of ceramic wastes in construction, 1, 197–214. Ceramic Materials. IntechOpen. https://doi.org/10.5772/intechopen.83933

Kannan, D. M., Aboubakr, S. H., EL-Dieb, A. S., & Reda Taha, M. M. (2017). High performance concrete incorporating ceramic waste powder as large partial replacement of Portland Cement. Construction and Building Materials, 144, 35–41. https://doi.org/10.1016/j.conbuildmat.2017.03.115

Keleştemur, O., Yildiz, S., Gökçer, B., & Arici, E. (2014). Statistical analysis for freeze–thaw resistance of cement mortars containing marble dust and glass fiber. Materials & Design, 60, 548–555. https://doi.org/10.1016/j.matdes.2014.04.013

Keshavarz, Z., & Mostofinejad, D. (2019). Porcelain and red ceramic wastes used as replacements for coarse aggregate in concrete. Construction and Building Materials, 195, 218–230. https://doi.org/10.1016/j.conbuildmat.2018.11.033

Khalil, N. M. (2014). Exploitation of the ceramic wastes for the extraction of Nano Aluminum Oxide Powder. Journal of Industrial and Engineering Chemistry, 20(5), 3663–3666. https://doi.org/10.1016/j.jiec.2013.12.063

Khattab, R. M., Wahsh, M. M. S., & Khalil, N. M. (2012). Preparation and characterization of porous alumina ceramics through starch consolidation casting technique. Ceramics International, 38(6), 4723–4728. https://doi.org/10.1016/j.ceramint.2012.02.057

Kostadinović, D., Jovanović, M., Bakić, V., Stepanić, N., & Todorović, M. (2022). Experimental investigation of summer thermal performance of the green roof system with mineral wool substrate. Building and Environment, 217, 109061. https://doi.org/10.1016/j.buildenv.2022.109061

Lassinantti, M., Mugoni, C., Guandalini, S., Cattini, A., Mazzini, D., Alboni, C., & Siligardi, C. (2018). Glass recycling in the production of low-temperature stoneware tiles. Journal of Cleaner Production, 197, 1531–1539. https://doi.org/10.1016/j.jclepro.2018.06.264

Lakhdar, Y., Tuck, C., Binner, J., Terry, A., & Goodridge, R. (2021). Additive Manufacturing of Advanced Ceramic Materials. Progress in Materials Science, 116, 100736. https://doi.org/10.1016/j.pmatsci.2020.100736

Liebermann, J. (2012). High-voltage insulators: Basics and trends for producers, users, and students (1) Fraunhofer Institute for Ceramic Technologies and Systems. ISBN: 9783877352083

Liu, T., Zhang, J., Wu, J., Liu, J., Li, C., Ning, T., Luo, Z., Zhou, X., Yang, Q., & Lu, A. (2019). The utilization of electrical insulators waste and red mud for fabrication of partially vitrified ceramic materials with high porosity and high strength. Journal of Cleaner Production, 223, 790–800. https://doi.org/10.1016/j.jclepro.2019.03.162

Marciano, S., Mugnier, N., Clerin, P., Cristol, B., & Moulin, P. (2006). Nanofiltration of Bayer Process Solutions. Journal of Membrane Science, 281(1-2), 260–267. https://doi.org/10.1016/j.memsci.2006.03.040

Matjie, R. H., Bunt, J. R., & Van Heerden, J. H. P. (2005). Extraction of alumina from coal fly ash generated from a selected low rank bituminous South African coal. Minerals Engineering, 18(3), 299–310. https://doi.org/10.1016/j.mineng.2004.06.013

Matteucci, F., Dondi, M., & Guarini, G. (2002). Effect of soda-lime glass on sintering and technological properties of porcelain stoneware tiles. Ceramics International, 28(8), 873–880. https://doi.org/10.1016/s0272-8842(02)00067-6

Mavrič, A., Valant, M., Cui, C., & Wang, Z. M. (2019). Advanced applications of amorphous alumina: From Nano to bulk. Journal of Non-Crystalline Solids, 521, 119493. https://doi.org/10.1016/j.jnoncrysol.2019.119493

Meena, R. V., Jain, J. K., Chouhan, H. S., & Beniwal, A. S. (2022). Use of waste ceramics to produce sustainable concrete: A Review. Cleaner Materials, 4, 100085. https://doi.org/10.1016/j.clema.2022.100085

Meng, Y., Gong, G., Wei, D., & Xie, Y. (2016). In situ high temperature X-ray diffraction study on high strength aluminous porcelain insulator with the AL2O3-SiO2-K2O-NA2O system. Applied Clay Science, 132-133, 760–767. https://doi.org/10.1016/j.clay.2016.07.014

Meng, Y., Gong, G., Wu, Z., Yin, Z., Xie, Y., & Liu, S. (2012). Fabrication and microstructure investigation of ultra-high-strength porcelain insulator. Journal of the European Ceramic Society, 32(12), 3043–3049. https://doi.org/10.1016/j.jeurceramsoc.2012.04.015

Merga, A., Murthy, H. C. A., Amare, E., Ahmed, K., & Bekele, E. (2019). Fabrication of electrical porcelain insulator from ceramic raw materials of Oromia Region, Ethiopia. Heliyon, 5(8). https://doi.org/10.1016/j.heliyon.2019.e02327

Mert, H. H., & Mert, M. S. (2021). Design of N-octadecane-based form-stable composite phase change materials embedded in porous nano alumina for thermal energy storage applications. Journal of Thermal Analysis and Calorimetry, 147(8), 4925–4934. https://doi.org/10.1007/s10973-021-10886-0

Mitchell, A., Lafont, U., Hołyńska, M., & Semprimoschnig, C. (2018). Additive Manufacturing - a review of 4D printing and future applications. Additive Manufacturing, 24, 606–626. https://doi.org/10.1016/j.addma.2018.10.038

Moraes, E., Sangiacomo, L., P. Stochero, N., Arcaro, S., R. Barbosa, L., Lenzi, A., Siligardi, C., & Novaes de Oliveira, A. P. (2019). Innovative thermal and acoustic insulation foam by using recycled ceramic shell and expandable styrofoam (EPS) wastes. Waste Management, 89, 336–344. https://doi.org/10.1016/j.wasman.2019.04.019

Morocutti, T., Berg, T., Muhr, M., & Godel, G. (2012). Developments of high voltage porcelain post-insulators. 2012 IEEE International Symposium on Electrical Insulation. https://doi.org/10.1109/elinsl.2012.6251497

Nepomuceno, M. C. S., Isidoro, R. A. S., & Catarino, J. P. G. (2018). Mechanical performance evaluation of concrete made with recycled ceramic coarse aggregates from industrial brick waste. Construction and Building Materials, 165, 284–294. https://doi.org/10.1016/j.conbuildmat.2018.01.052

Owoeye, S. S., Toludare, T. S., Isinkaye, O. E., & Kingsley, U. (2019). Influence of waste glasses on the physico-mechanical behavior of Porcelain Ceramics. Boletín De La Sociedad Española De Cerámica y Vidrio, 58(2), 77–84. https://doi.org/10.1016/j.bsecv.2018.07.002

Palaniyappan, S., Veiravan, A., Kaliyamoorthy, R., & Kumar, V. (2021). Sustainable solution to low-cost alternative abrasive from electric ceramic insulator waste for use in abrasive water jet machining. https://doi.org/10.21203/rs.3.rs-606563/v1

Papailiou, K. O., & Schmuck, F. (2013). Silicone composite insulators. Power Systems, 1, 197-283. doi:10.1007/978-3-642-15320-4

Piyaphanuwat, R., & Asavapisit, S. (2017). Utilization ceramic wastes from porcelain ceramic industry in lightweight aggregate concrete. International Journal of Environmental Science and Development, 8(5), 342–346. https://doi.org/10.18178/ijesd.2017.8.5.975

Portella, K. F., Joukoski, A., Franck, R., & Derksen, R. (2006). Reciclagem Secundária de Rejeitos de porcelanas elétricas em estruturas de concreto: Determinação do Desempenho Sob Envelhecimento Acelerado. Cerâmica, 52(323), 155–167. https://doi.org/10.1590/s0366-69132006000300008

Rodríguez, E. A., Niño, C. J., Contreras, J. E., Vázquez, F. J., López-Perales, J. F., Aguilar-Martínez, J. A., Puente-Ornelas, R., & Lara-Banda, M. (2019). Influence of incorporation of fired porcelain scrap as partial replacement of quartz on properties of an electrical porcelain. Journal of Cleaner Production, 233, 501–509. https://doi.org/10.1016/j.jclepro.2019.05.403

Ruys, A. (2019). Refractory and other specialist industrial applications of alumina. Alumina Ceramics, 473–499. https://doi.org/10.1016/b978-0-08-102442-3.00015-4

Sabaa, Z. M., & Fahad, B. M. (2018). Glass and porcelain waste as abrasives investigated at different conditions. IOP Conference Series: Materials Science and Engineering, 454, 012117. https://doi.org/10.1088/1757-899x/454/1/012117

Sabaa, Z. M., & Fahad, B. M. (2019). Utilization of construction waste to developing an abrasive material. Journal of Engineering and Applied Sciences, 14(8), 2582–2587. https://doi.org/10.36478/jeasci.2019.2582.2587

Said, S., Mikhail, S., & Riad, M. (2019). Recent progress in preparations and applications of Meso-porous alumina. Materials Science for Energy Technologies, 2(2), 288–297. https://doi.org/10.1016/j.mset.2019.02.005

Sekar, T., Ganesan, N., & Nampoothiri, N. (2011). Studies on strength characteristics on utilization of waste materials as coarse aggregate in concrete. International Journal of Engineering Science and Technology. 3(7), 5436–5440. ISSN: 0975-5462

Sepehri, A., & Sarrafzadeh, M.-H. (2018). Effect of nitrifiers community on fouling mitigation and nitrification efficiency in a membrane bioreactor. Chemical Engineering and Processing - Process Intensification, 128, 10–18. https://doi.org/10.1016/j.cep.2018.04.006

Shah, K. W., & Huseien, G. F. (2020). Utilizing ceramic wastes in the concrete industry. Recycled Ceramics in Sustainable Concrete, 33–48. https://doi.org/10.1201/9781003120292-3

Siddique, S., Shrivastava, S., & Chaudhary, S. (2018a). Evaluating resistance of fine bone china ceramic aggregate concrete to sulphate attack. Construction and Building Materials, 186, 826–832.https://doi.org/10.1016/j.conbuildmat.2018.07.138

Siddique, S., Shrivastava, S., Chaudhary, S., & Gupta, T. (2018b). Strength and impact resistance properties of concrete containing fine bone china ceramic aggregate. Construction and Building Materials, 169, 289–298. https://doi.org/10.1016/j.conbuildmat.2018.02.213

Siddique, S., Chaudhary, S., Shrivastava, S., & Gupta, T. (2019). Sustainable utilisation of ceramic waste in concrete: Exposure to adverse conditions. Journal of Cleaner Production, 210, 246–255. https://doi.org/10.1016/j.jclepro.2018.10.231

Sun, J., Ye, D., Zou, J., Chen, X., Wang, Y., Yuan, J., Liang, H., Qu, H., Binner, J., & Bai, J. (2023). A review on additive manufacturing of ceramic matrix composites. Journal of Materials Science & Technology, 138, 1–16. https://doi.org/10.1016/j.jmst.2022.06.039

Tam, V. W. Y., Soomro, M., & Evangelista, A. C. (2018). A review of recycled aggregate in concrete applications (2000–2017). Construction and Building Materials, 172, 272–292. https://doi.org/10.1016/j.conbuildmat.2018.03.240

Tikul, N. (2014). Assessing environmental impact of small and medium ceramic tile manufacturing enterprises in Thailand. Journal of Manufacturing Systems, 33(1), 1–6. https://doi.org/10.1016/j.jmsy.2013.12.002

Zengrong, Y., Xinghua, Z., & Kangming, M. (2013). Patente de China No. CN102951897A. Washington, DC: U.S. Patent and Trademark Office. https://patents.google.com/patent/CN102951897A/en#patentCitations

PDF

PDF

FLIP

FLIP